Beyond Capsicum and Tomato: Smarter Crops and Precision Farming Technologies Make Polyhouses Truly Profitable

- Benjamin Raja

- Oct 2, 2025

- 6 min read

Polyhouse farming in India has often been associated with high-value vegetables such as capsicum, cucumber, and tomato. However, these crops face price volatility, perishability, and market dependency, making profitability uncertain. A more sustainable approach is to diversify into industrial crops like turmeric and ginger, or direct-to-consumer crops like coriander and spinach, while leveraging substrates such as cocopeat and precision systems like GroTron® for irrigation, fertigation, and climate automation.

1. The Economics of Vegetable Crops in Polyhouses

Capsicum: 32–80 tonnes/acre/year. At ₹20–60/kg, gross revenue is ₹6.4–48 lakh/acre. But when prices fall to ₹8–12/kg, farmers incur heavy losses.

Tomato/Cherry Tomato: 100–120 tonnes/acre/year. Despite high potential, often market crashes to ₹5–10/kg erode profitability.

Cucumber: 100–150 tonnes/acre/year, but distress sales at ₹4–6/kg are common, leaving little margin.

Takeaway: Vegetable crops in polyhouses are technically feasible but economically risky due to price instability and perishability.

2. High Labour and Management Demands of Vegetable Crops

While vegetables such as capsicum, cucumber, and tomato are technically suitable for polyhouses, their labour requirements are disproportionately high:

Pruning & Training

Capsicum and tomato require continuous pruning of side shoots and removal of old leaves.

Indeterminate tomato and cucumber vines must be trained and supported with trellis systems, often adjusted weekly.

Pest and Disease Management

High humidity in polyhouses increases risk of fungal diseases (powdery mildew, downy mildew).

Thrips, whiteflies, and mites require weekly or bi-weekly pesticide sprays, adding both cost and health risks.

Frequent Harvesting

Tomato: harvested every 2–3 days.

Cucumber: every alternate day.

Capsicum: every 4–5 days.

Labour for harvesting alone may account for 20–25% of recurring costs.

Post-Harvest Handling

Vegetables are highly perishable — shelf life is 2–5 days without cold storage.

Requires grading, packaging, and fast movement to market. Losses of 10–15% during handling are common.

Implication: For small and medium farmers, labour cost can consume 35–40% of gross revenue in vegetable polyhouses. Combined with unpredictable prices, this leads to unstable profitability.

3. Alternative Crops: Turmeric and Ginger — The Smart Choice for Polyhouses

Turmeric and ginger, both rhizomatous crops, are highly suited for polyhouse cultivation when grown in cocopeat substrates with precision fertigation. Unlike vegetables, these crops offer technical advantages that make them low-maintenance and more resilient to market fluctuations.

3.1 Low-Maintenance Agronomy

Minimal canopy management: Unlike capsicum and tomato, there is no need for pruning, thinning, or trellising. Once planted, turmeric and ginger follow a uniform vegetative cycle with limited intervention.

Lower pest/disease incidence:

Cocopeat-based cultivation greatly reduces soil-borne pathogens such as rhizome rot (Pythium, Fusarium).

Routine preventive sprays are sufficient, compared to weekly pesticide interventions needed in vegetables.

Reduced labour: Only periodic fertigation adjustments and irrigation management are required.

3.2 Single-Harvest Nature

Both turmeric and ginger are single-harvest crops with a crop cycle of 8–10 months.

This removes the need for frequent harvesting and handling, lowering labour inputs and post-harvest losses.

3.3 Flexibility Against Market Price Fluctuations

Ginger:

If prices crash during harvest season, the crop can be left in-situ for a few extra months. Mature rhizomes continue bulking, effectively “storing underground” until prices stabilize.

Alternatively, fresh ginger can be processed into dry ginger or ginger powder, both with higher shelf life and better price stability.

Turmeric:

After harvest, raw turmeric rhizomes can be boiled, dried, and polished, increasing storability up to 1–2 years.

Value addition into turmeric powder, oleoresin, or curcumin extraction provides long-term storage and premium pricing opportunities.

3.4 Technical Fit for Polyhouse Systems

Canopy architecture: Broad leaves of turmeric and ginger intercept light efficiently at moderate PPFD levels (500–700 µmol/m²/s), reducing stress under partially shaded polyhouse conditions.

Rooting pattern: Rhizomes develop compactly in cocopeat grow bags, ensuring high aeration and preventing compaction — a common yield-limiting factor in soil.

Water and nutrient needs: Both crops require relatively stable EC (1.8–2.0 mS/cm) and slightly acidic pH (5.5–6.5), conditions that can be precisely maintained via GroTron automation.

4. Light, Humidity, and CO₂ Management for Turmeric and Ginger in Polyhouses

Turmeric (Curcuma longa) and ginger (Zingiber officinale) are shade-loving rhizomatous crops that evolved under subtropical forest canopies, where filtered light, high humidity, and stable CO₂ levels prevail. In a polyhouse, these environmental parameters can be engineered precisely to replicate those conditions — unlocking yield potential well beyond open-field farming.

4.1 Light Environment: PAR & PPFD Requirements

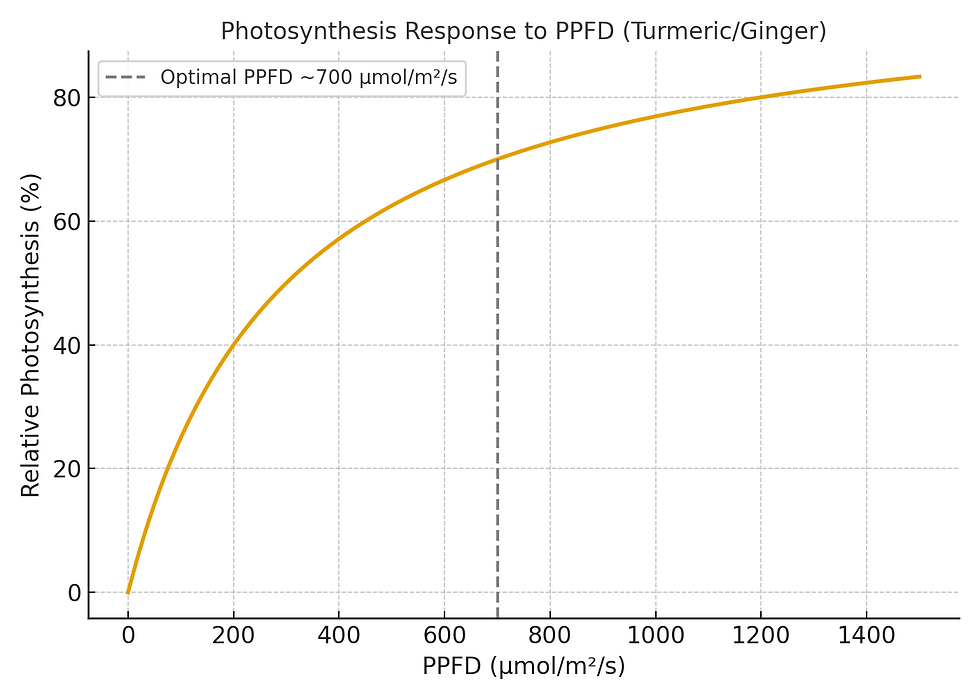

Photosynthetically Active Radiation (PAR): Both turmeric and ginger are C3 plants with a relatively low light saturation point compared to fruiting vegetables.

Photosynthetic Photon Flux Density (PPFD):

Optimal canopy-level PPFD: 500–700 µmol/m²/s.

Beyond ~800 µmol/m²/s, photosynthetic efficiency plateaus, and excess light energy increases transpiration load.

Practical Interpretation:

Natural tropical sunlight = ~1800–2000 µmol/m²/s.

Polyhouse cladding + shade nets reduce this to ~1000–1200 µmol/m²/s.

Additional internal shading or diffused films can bring canopy PPFD into the ideal range for rhizome crops.

4.2 Humidity and Vapor Pressure Deficit (VPD)

VPD Definition: The difference between the vapor pressure inside the leaf and the surrounding air. It drives transpiration, nutrient uptake, and stomatal behavior.

Optimal Range for Turmeric/Ginger: 0.9–1.1 kPa.

Interpretation:

Low VPD (<0.5 kPa): Air too humid → stomata close → reduced nutrient uptake and higher fungal risk.

High VPD (>1.5 kPa): Air too dry → excessive transpiration → leaf rolling, tip burn, and nutrient imbalances.

Ideal VPD ensures maximum stomatal conductance and steady CO₂ intake → consistent photosynthesis and rhizome bulking.

4.3 Carbon Dioxide (CO₂): The Forgotten Limiting Factor

Ambient CO₂: ~420 ppm (2025 global average).

Optimal Range for Turmeric/Ginger: 800–1000 ppm during active photoperiod.

Polyhouse Scenarios:

Naturally Ventilated Polyhouse: Relies on ambient CO₂. Photosynthesis limited to ~70% of potential due to dilution during peak transpiration hours.

Closed Polyhouse with CO₂ Enrichment: Controlled injection maintains 800–1000 ppm. This can enhance rhizome yield by 40–70%.

4.4 Integration Through GroTron® — AI-Driven Precision Farming Technologies for Rhizome Crops

Managing a polyhouse environment is not simply about switching on irrigation pumps or foggers. It is a dynamic balancing act between water, nutrients, light, humidity, and CO₂. Traditionally, this required a skilled agronomist monitoring parameters daily. With GroTron®, the best of the available Precision Farming Technologies, this expertise is embedded into the system itself.

Dynamic Management of Critical Parameters

EC / pH (Nutrient Solution)

GroTron continuously measures real-time electrical conductivity (EC) and pH of the fertigation solution.

AI models adjust dosing pumps in milliseconds, ensuring ginger and turmeric roots always receive nutrients within their optimal range (EC 1.8–2.0 mS/cm, pH 5.5–6.5).

Prevents hidden yield losses from silent nutrient imbalances that farmers often miss.

PAR & PPFD (Light Environment)

Using precision quantum sensors, GroTron monitors how much usable light actually reaches the crop canopy.

If PPFD rises above 700 µmol/m²/s, automatic shading or misting reduces light stress.

If it dips below 500 µmol/m²/s (e.g., cloudy days), GroTron adjusts irrigation and nutrient flow to balance energy supply with demand — avoiding stress from “luxury consumption.”

VPD (Vapor Pressure Deficit)

GroTron integrates leaf temperature, air humidity, and canopy-level climate data to calculate real-time VPD.

AI-driven fan–pad and fogger systems are triggered to keep VPD tightly within 0.9–1.1 kPa — the sweet spot for rhizome bulking.

This ensures stomata remain open, maximizing nutrient uptake and photosynthetic CO₂ assimilation.

CO₂ Enrichment

In closed polyhouses, GroTron monitors and maintains CO₂ levels between 800–1000 ppm.

Rather than dosing blindly, it syncs CO₂ enrichment with VPD and light levels:

High PPFD + optimal VPD → more CO₂ dosing.

Low PPFD or high VPD → reduced dosing, preventing waste.

This synergy can boost turmeric and ginger yields by 25–30% compared to ambient CO₂ systems.

Why GroTron® is Different

AI at the Core: GroTron doesn’t follow rigid schedules; it predicts plant demand using AI algorithms trained on years of crop–climate–yield data.

Patented Technology: Recognized among India’s Top 100 Innovations of 2023, GroTron carries patents in precision fertigation and dynamic irrigation algorithms — ensuring unmatched performance.

Holistic Automation: Instead of multiple controllers for fertigation, climate, and CO₂, GroTron unifies everything into one seamless brain for the polyhouse.

Farmer-Proof Design: Its intuitive dashboard translates complex agronomy into actionable visuals (green zone = optimal, red zone = corrective action). Even a non-technical farmer can run a high-tech polyhouse profitably.

5. Conclusion

Polyhouse farming in India is at a crossroads. While vegetables like capsicum, tomato, and cucumber have dominated the early years, their labour intensity, perishability, and market volatility have left many farmers disappointed. By shifting focus to resilient alternatives like turmeric and ginger, supported by substrates such as cocopeat and precision climate–nutrition control through GroTron®, farmers can achieve not only higher yields but also predictable, stress-free income. When PAR, PPFD, VPD, CO₂, EC, and pH are managed dynamically through GroTron’s patented AI-driven platform, crops grow to their true genetic potential, while inputs and risks are minimized. This is more than just automation — it is a transformation of farming into a science-led, future-ready, and profitable enterprise. Polyhouse farmers who adopt this shift will no longer be at the mercy of unstable markets, but will lead the way into a new era of sustainable and intelligent agriculture.

Comments